Location: Littleton, Colorado

Symptoms: Weak flipper, lower playfield general illumination not working.

I started with the flipper. I checked the mechanical aspects of the flipper by manually turning it. Then I checked the end-play by lifting it up and down, and tried to rock it back and forth to check whether the flipper bushing should be replaced. Mechanically, everything seemed fine.

Next I turned to the electrical aspects of the flipper. Flippers of this type have two coils wrapped around the solenoid coil bobbin. One coil provides a strong magnetic field for starting the movement of plunger (slug) into the solenoid. The other coil provides a weaker magnetic field for holding the plunger once it has been drawn inside the bobbin. The force required to hold the plunger is less than what it takes to draw it in.

When the flipper button is pressed, both coils are initially energized. Once the flipper is at it’s ending position, it opens a switch that turns off the more powerful coil and leaves the weaker coil energized. This allows the flippers to be strong, but prevents them from burning up if someone were to hold the flipper button. If power were applied constantly to the more powerful coil, it would overheat and start burning.

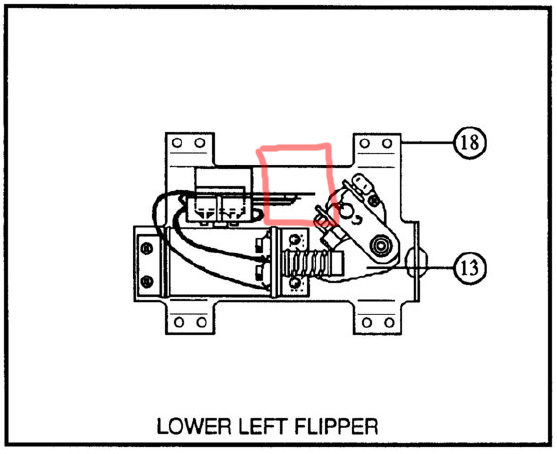

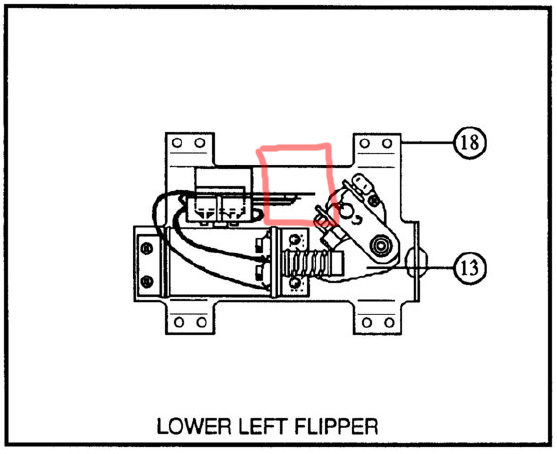

The switch that opens when the flipper reaches its end position is called the End of Stroke switch (EOS). I check the EOS switch with the power off and the flipper in its normal resting position with my ohm-meter, and it was “open”, when it should have registered a short. I cleaned the contacts with some 440 grit sandpaper, and adjusted the contacts to make sure they were closing when the flipper was at rest.

Drawing of flipper unit from the Police Force manual, showing the End of Stroke switch.

I rechecked the switch contacts with the ohm-meter and they were working properly. We powered-up the machine to verify the flipper was working fine. Basically, since the switch wasn’t closing, the flipper was only running with the weaker coil.

Next I took a look at why all of the General Illumination (GI) lights in the bottom half of the playfield were not working. The GI lights are the ones that stay illuminated all of the time and light up the plastics and the playfield areas so that you can see the ball.

First I checked to make sure no voltage was present at one of the light sockets. Although it was a remote chance, I wanted to be sure that it wasn’t just a case of the lights being burned out (which could have happened if there was a short with a higher voltage somewhere else in the machine). There was no voltage (be sure to measure on AC scale). I checked where the power was coming from the Backbox Interconnect board, and there was 6.3 volts there. So somewhere between the backbox and the playfield, the voltage was getting lost.

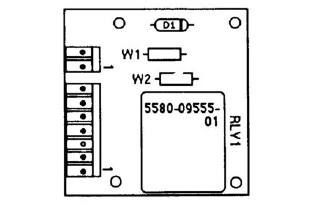

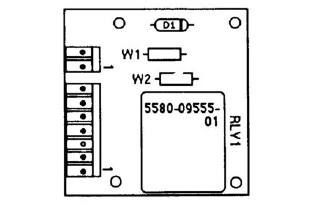

I tipped the playfield all of the way up and found the GI Relay on a small circuit board at the very bottom edge. The connectors that connect the wires to the board were burnt and falling apart. The connector on the circuit board was burnt as well.

Connector failure is a common problem with GI lighting in pinball machines. Oxidation builds up on the connector pin, or the crimp, and causes the resistance of the connection to go up. This causes the connector to heat up until it fails. Because each machine and manufacturer uses different types and sizes of connectors, it’s difficult to to keep connectors on hand. In this case, I didn’t have replacements with me.

The owner didn’t want to wait to get the proper connectors and asked that I solder the wires directly to the circuit board. I did so, and the lights all worked fine after that. Normally I am a purist about having the connectors fixed properly, but in this case the connectors only served to make the board replacement easier, which is unlikely to ever need replacing.

GI lamp relay board.

We checked and replaced several burned out lights. The game was working well and in good condition.