Symptoms: 50 or 5000 points repeatedly scoring.

Locations: Denver and Fort Collins

I’ve worked on several Space Mission pinball machines over the past 3-4 years. One problem they’ve had in common is the sometimes the 50 or 5000 point relays will get stuck and stay engaged. The problem would often go away when I raised the playfield, making it very difficult to diagnose.

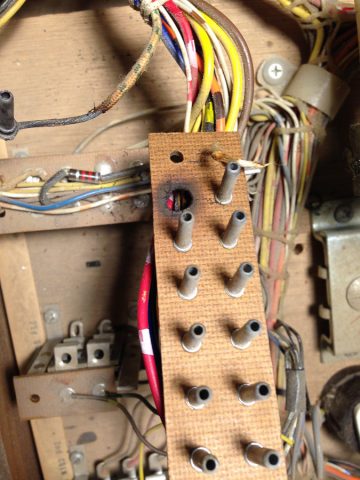

The 50 and 5000 point relays are mounted on the underside of the playfield in the upper left corner (lower left when playfield is raised and viewed from the underside).

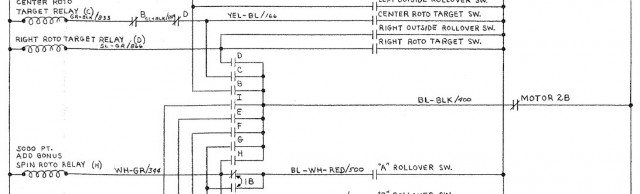

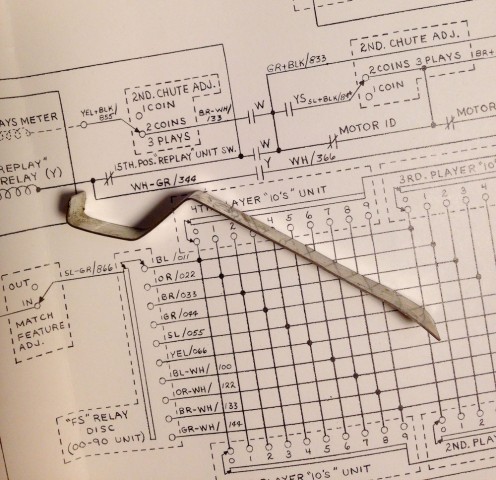

The problem is the main wiring harness which comes onto the playfield on the right side shorts against the bracket holding one of the stepper units. Over the years repeatedly raising and lowering the playfield causes the edge of stepper bracket to wear through the insulation on some of the wires in the main harness. The stepper bracket has voltage on it via the main Yellow power supply wire. This creates an intermittent short between the Yellow supply wire and whatever wire(s) on the outside of the harness which happen to have their insulation compromised.

The symptoms are variable with the most common problem being the 50 and 5000 point relays staying on. But I’ve seen other symptoms including hitting the center target when the 5000 point lamp is lit and not scoring and not scoring bonus points at the end of the ball. One machine had 3 wires that were occasionally shorting against the bracket which caused constantly changing symptoms, most of which would go away when the playfield was raised.

The fix is to remove the stepper unit near where the harness attaches to the playfield and then remove the screws holding the harness clamps. Wrap the harness with several layers of electrical tape near where the bracket is. Then reattach the clamps and the stepper unit.

I will try to remember to take some photos next time I work on a Space Mission and update this post. Often the last thing I’m thinking about when I’m at a customer’s working on their machine is taking photos of what I’m doing. A picture is worth a 1000 words.