Location: Arvada, CO

Symptoms: Blows playfield coil fuses; needs new rubbers and bulbs, cleaning.

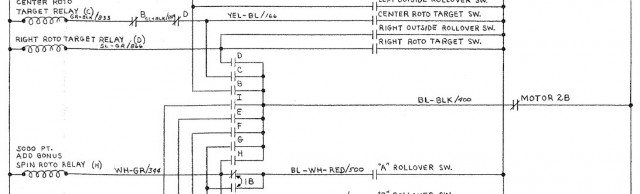

I started by replacing both playfield fuses since they were blown. When I started a game, the kicker at the outhole started firing randomly, sometimes very rapidly. The sensing switch seemed to be fine. I also noticed that some of the pop bumpers weren’t firing correctly. If I pressed on the left pop bumper skirt, the center pop bumper would fire. Basically there was something not right with the solenoid driver circuit.

I started with the signal for the kicker coil, and with the oscilloscope, I traced it back through the solenoid driver board. The signal going into driver transistor Q11 was going crazy. I went further back to the output of the 74154 decoder chip (U2) and the signal (pin 15) was still crazy and random looking. No wonder the fuses blew.

I checked the input signals to the 74154 and the “B” signal was randomly moving between 1 and 2 volts. This is neither a digital “1” or “0” and it makes digital circuits act randomly. I traced the signal further back to the MPU board to the output of the 6820 PIA (U11, Pin 11). Since the 6820 was already in a socket, I lifted it out of the socket and bent pin 11 out, then put the 6820 back in. This isolated pin 11 from the rest of the circuit to make sure that nothing else was interfering with the signal. The oscilloscope showed it was still bad.

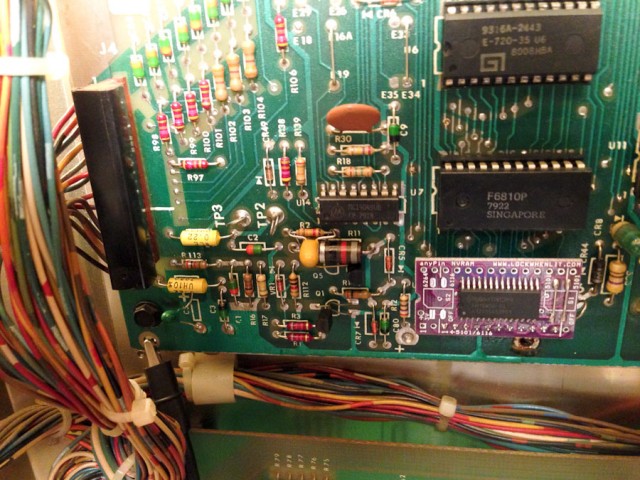

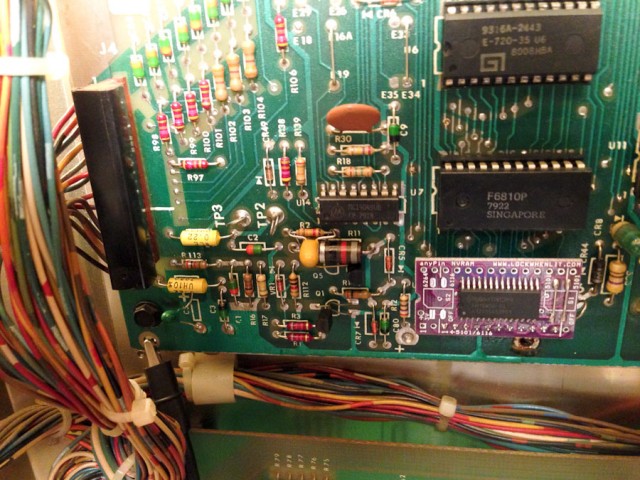

6820 PIA chip with pin 11 lifted to isolate it from the rest of the circuit.

The faulty “B” signal would also cause the wrong pop bumpers (and other solenoids) to fire.

I replaced the 6820 with a 6821 (they are interchangeable) Also, I replaced the 5101 RAM chip on the MPU board with an AnyPin NVRAM module and removed the battery from the circuit board. This will save the MPU board from future corrosion caused by battery gasses.

At this point the machine was working well, except it wouldn’t boot about 50% of the time. It looked like a problem with the reset circuit. Bally didn’t include a time delay in the reset circuit like most other manufacturers. I added a 4.7 uF tantalum capacitor across R2 to give the reset a little bit of time delay when it boots. It solved the problem and booted 100% of the time after that.

4.7uF capacitor added across R2 to assist reset circuit. The positive pin of the capacitor is connected to the right side of R2. AnyPin NVRAM module in lower right.

Finally, all of the rubbers were replaced, bad bulbs replaced, and the playfield cleaned and waxed. Some of the light sockets needed cleaning because the bulbs weren’t making good connections.