Symptoms: Upper playfield pop bumper not working, lower playfield up kicker not working, playfield GI lights off, sticky flipper on lower playfield.

Location: Golden, CO

Sometimes when approaching a Gottlieb Systems 80 pinball machine, especially the Haunted House and Black Hole, which utilize different playfield levels, it’s easy to get overwhelmed. It’s good to stay focused on one problem at a time.

For the first issue, the pop bumper on the upper playfield had a broken wire. Re-soldered the wire to the coil, and we checked that off the list.

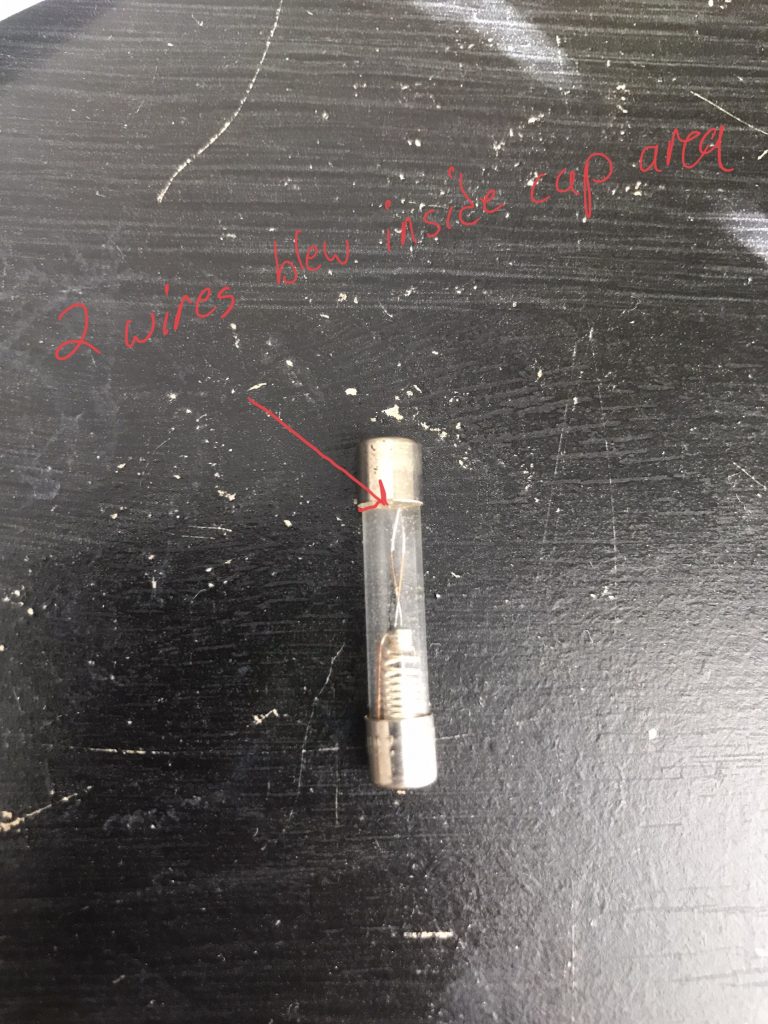

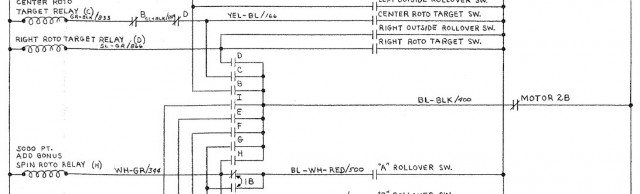

The next issue was the playfield lights not working. I found that the GI lighting fuse was blown. I replaced it, which solved the problem temporarily. I discovered later, while solving problems with the lower playfield, that the fuse blew again. The “U” relay controls the power to the lights and the solenoids on the lower playfield. When the machine senses the ball dropping down to the lower playfield, the “U” relay is activated. It turned out, the lighting fuse would blow whenever the “U” relay activated. That meant there was short in the lighting circuit on the lower playfield.

I’ve seen shorted lamp sockets on these machines in the past, where the center conductor pin shorts against the can of the socket. I checked each GI light socket and found one that was shorted on the left side. I bent the pins so they wouldn’t short, replaced the fuse and manually actuated the “U” relay, and the lights lit and the fuse didn’t blow again.

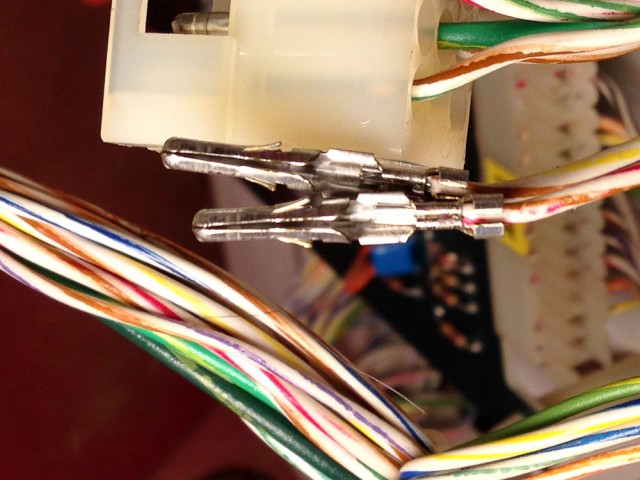

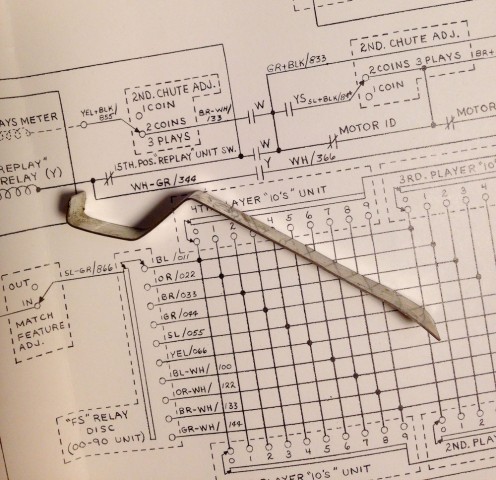

The problem with the lower playfield up-kicker was traced back to the big edge connector on the bottom of the Driver Board. The ground for that circuit was not making a good connection. I removed the old pin from the connector and replaced it with a new one.

When checking the operation of all of the controlled lamps, there was one lamp not coming on at all. I replaced the bulb, but that didn’t help. I traced the problem back to the Driver Board. It appeared the transistor was blown. I replaced the transistor and it still didn’t work. It turned out that once again, this was a faulty connection at the card edge connector, except this time the pin was shorting across the row to another pin deep inside the connector, thus grounding out the circuit. This is what caused the original transistor to blow. I replaced the pin and the lamp started working again.

After replacing a few bad bulbs, the machine was working and playing well.