Location: Lakewood, CO

Symptom: Loud hum on speaker outputs, amplifier rebuild.

As usual with an amplifier of this vintage, all of the electrolytic capacitors were replaced. This fixed the problem with the loud hum. Also one of the electrolytic capacitors was causing a bias problem with one of the preamp transistors, causing that channel to be weak.

After the capacitor replacement, I was testing the amp with the oscilloscope, there was still one channel substantially weaker than the other, and both channels had non-linearity distortion. I traced this to the AVC (Automatic Volume Control) circuit. The AVC circuit is used to level the volume between different records and different sides.

The AVC circuit uses the resistance through diodes to achieve this. The resistance of the diodes changes with the amount of current flowing through it. The louder the song, the more current flows through the diodes, the lower the resistance, which lowers the volume.

The problem with this vintage of amplifiers is they used selenium diodes. These diodes seem to fail with age. In this case, diodes in both CR103 and CR104 were bad. One was nearly open, another nearly shorted. The resistance across the other diodes was high. My multimeter couldn’t properly read them, so I relied on just measuring voltages across them.

Small selenium diodes are no longer made.Silicon diodes can be used, however, you have to use more than two in series for each selenium diode you replace. I started with using two 1N914 diodes for each diode in CR103 and CR104. The resistance was too low and my signal going into V101 was too weak. So I doubled them, using four 1N914 diodes for each diode in CR103 and CR104. That was 16 diodes total.

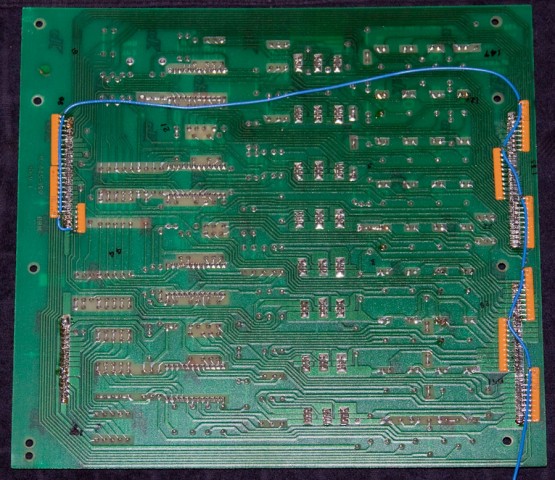

Rework showing the strings of four 1N914 diodes in the AVC circuit. One string is exposed, the others are in the green shrink tubing.

I also replaced the CR102 diode pair. For this, a single 1N914 can be used for each diode in CR102. After taking some measurements, I could have used three diodes for each, instead of four. But with four, I get a little more input into the V101 tube (about 120mV) without causing clipping on the output.

The amp is now working great!

So if you’re rebuilding an amp with selenium diodes in the AVC circuit, replace them with 3 or 4 1N914 diodes in series for each diode in CR103 and CR104 and use single diodes for CR102. It ends up being a lot of diodes, but they are small and cheap.