Location: Highlands Ranch, Colorado

Symptom: No Sound

The owner of this machine had sent both the original CPU board and the Sound board to a pinball repair company located in Illinois. The owner had found this company listed on E-bay. He said neither board worked when he received them back.

The owner also had a after-market CPU board made by Ni-Wumpf installed in the game. It operated without problem (although without sound). So we used Ni-Wumpf to figure out why the sound board wasn’t working.

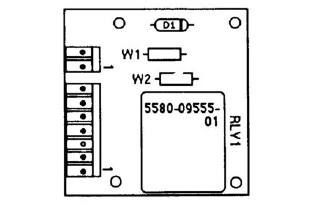

After checking supply voltages, I traced the audio signal with my oscilloscope. I could see the audio coming out of the sound generator chip and going into the audio amplifier chip. But there was nothing coming out of the amp chip (LM380N). I verified that the output circuit wasn’t shorted, so everything was pointing towards a bad LM380N. I would need to need to take the board back to my office for repair.

Next, I turned my attention to the original Gottlieb Systems 80 CPU board. The fact that the Ni-Wumpf would work with the game, indicates the pinball machine itself was not the cause of the original CPU board not working. The Illinois pinball repair company was blaming the slam-tilt circuit for the board not working. We checked the slam-tilt wiring and it was not at fault. In fact, someone had soldered the slam-tilt wires together so that it would never activate. The symptom was that the game wouldn’t boot-up and would cycle the Tilt Relay about once per second. Searching the internet revealed that this is usually associated with a bad or corrupt ROM.

Obviously, neither board was fully tested before leaving the pinball repair company in Illinois. Also, the ICs they replaced were sanded and painted. In my opinion, no reputable repair service will do this. I can’t even imagine why they do this. The sanding can cause a huge build-up of static electricity, which will damage the chips. I also noticed the sound board card edge connector was sanded. We don’t know if the other repair company did this, but someone had sanded through the tin and nickel plating, which doesn’t oxidize very fast, down to the bare copper which oxidizes rapidly like a penny does. Oxidation will cause the contacts to develop a high electrical resistance and cause lots of intermittent problems. The best way to clean a circuit board edge connector is to use a pencil eraser and follow up with some denatured alcohol to remove any oil residues.

We didn’t do any further testing with the CPU board because the owner wants the other pinball repair company to make it right.

I brought the sound board back to my office. I purchased an LM380N at JB Saunders in Boulder, and de-soldered the faulty chip and replaced it. I connected a power supply to the board and with a signal generator, injected a signal into the input and verified the amplified signal was on the output. The datasheet states the LM380 has a voltage gain of 50. 0.2V input was amplified to 10V on the output.

I shipped the board back to the owner. Before reinstalling the sound board, I had him check to make sure there was no voltage on the speaker wire. The presence of a voltage would indicated the speaker wire was shorted someplace and would probably damage the sound board. He reinstalled the sound board and everything worked.