Location: Greeley, Colorado.

Symptoms: Many. Bulbs out, trap door not working, a pop bumper not working, both sling-shots not working, flipper sticking, etc. Needed general servicing.

The biggest mystery with this machine was that every GI (General Illumination) bulb was burned out, except for 3. I suspect that at some point in the past, there was a GI short to a solenoid supply which blew most of the bulbs.

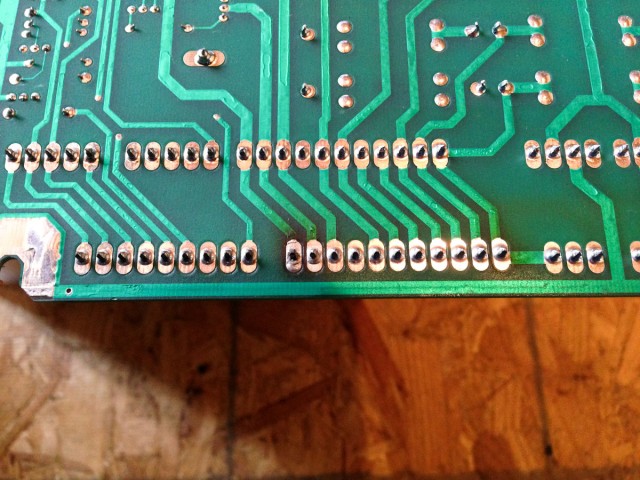

As I was replacing some of the controlled lamps, I discovered some that were burning very brightly. This raised a red flag that one of the rows or columns in the lamp matrix was stuck on. The easy way to check this is to go into the test menu and run the single lamp test. If more than one light comes on at a time, then the row or column driver is shorted or bad. It turned out to be Column 8 and the TIP107 transistor. All of the Column 8 lamps would light when any of the other columns were on. After replacing the transistor, the controlled lamps all worked except one.

The one lamp that didn’t work was the “Open Trapdoor W/Flashing” light. It was lighting when any other column or row was lit. In other words, the only time it acted normal was when any thing in its own column or row was lit. At first I thought it was a shorted diode. The diode tested OK with the meter. But the meter doesn’t test the diode at greater than 3 volts. So I snipped it and the light should have gone dark, but it didn’t. It turns out, someone had soldered the wires onto the socket incorrectly and bypassed the diode. Once I corrected the wiring, it worked fine.

As for the sticking flipper, it was a bad link that was catching on the end of the solenoid. I replaced the links, plungers and rubbers on both lower flippers. The upper flipper looked good enough to leave alone.

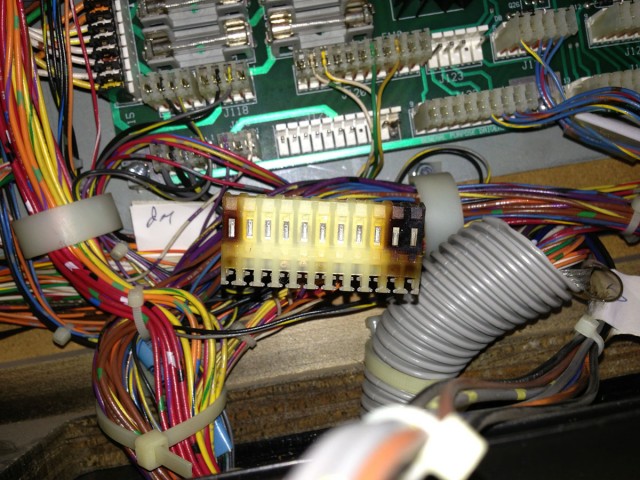

The other solenoid problems were all related to broken wires.

The trap door wasn’t working because the end of the spring broke on the solenoid that latches it up. I found the spring in the bottom of the machine and made a new hook with my pliers, and reattached it.

The game had an L4 version Game ROM (U6) installed. The most recent official version is L9, plus there is an L9.05H, which is a home version with some additional features. The difference between and L4 and L9H requires a move to a larger ROM (1 Mb to 2 Mb), plus one of the sound ROMs (U18) had to get upgraded to L3.

The L9H ROM images I downloaded from ipdb.org didn’t really match the documentation. The U6 ROM image was a 4 Mb image, and U18 was a 2 Mb image. In this Funhouse machine, both of these parts were 1 Mb so I couldn’t erase and re-program. I was out of 2 Mb EPROMs. So I ordered some blank 2 Mb parts from Marco and received 4 Mb parts instead. Ugh! I looked at the schematic for the sound board and saw that it would support a 4 Mb ROM. So, I programmed both images into 4 Mb EPROMs. This works fine for U6, but for U18 it doesn’t work without loading the code into the upper half of the EPROM to make it look like a 2 Mb part. Although the sound board hardware supports the 4 Mb ROMs, the firmware in the other sound ROMs doesn’t.

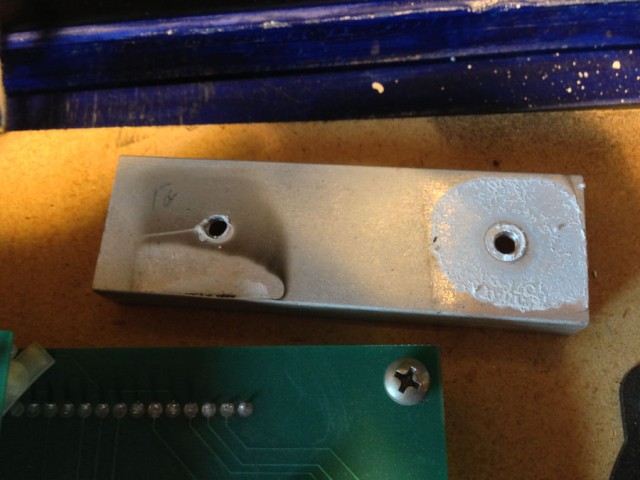

A note on CPU jumpers for larger ROMs: I think by default, the early WPC games had the W2 jumper installed. W2 supports the 28 pin ROM families and will still work with a 1 Mb 32-pin ROM because the associated pin on the 1 Mb ROM is not used. But anything larger (2 Mb or greater) will need the W2 jumper removed and the W1 jumper installed. The W1 jumper supports all of the 32-pin ROM families. So when using a 1 Mb ROM, the jumper can be in either position.

The same is true for the sound board with regards to U18. Jumper W4 supports the 28-pin families and jumper W3 supports the 32-pin families, with the 1 Mb ROMs not caring which position the jumper is in. But keep in mind that at least for Funhouse, the sound system firmware doesn’t support anything larger than a 2 Mb ROM in U18.

After correcting dozens of small problems, the pinball machine is looking and working great!