Location: Windsor, Colorado.

Symptom: Dead, with a slight humming sound.

When powered up, a slight humming sound would come from the speakers, indicating that at least part of the machine was getting power. No lights were coming on and the MPU was not booting.

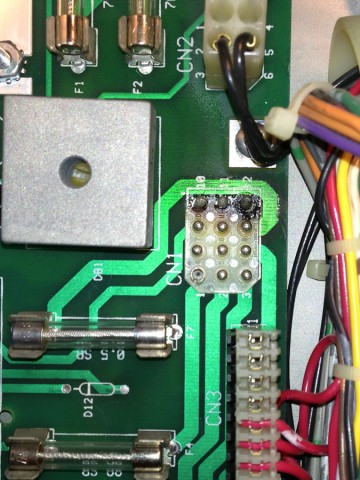

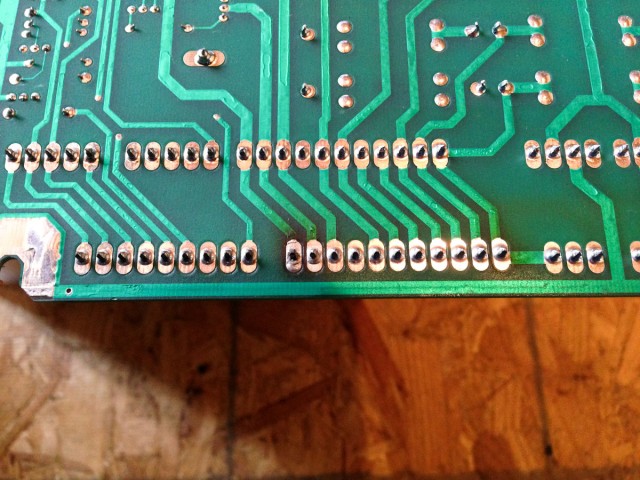

Checking the fuses, I found fuse (F113) bad, which powers the 5V logic circuit. I replaced the fuse and it blew again within a few seconds. I unplugged the MPU board and the 5 volt supplies to the playfield. With my multimeter, I determined a short existed on the power/driver board. I suspected the bridge rectifier had failed. Checking the rectifier I was able to confirm a shorted diode between one of the AC inputs and the “+” output.

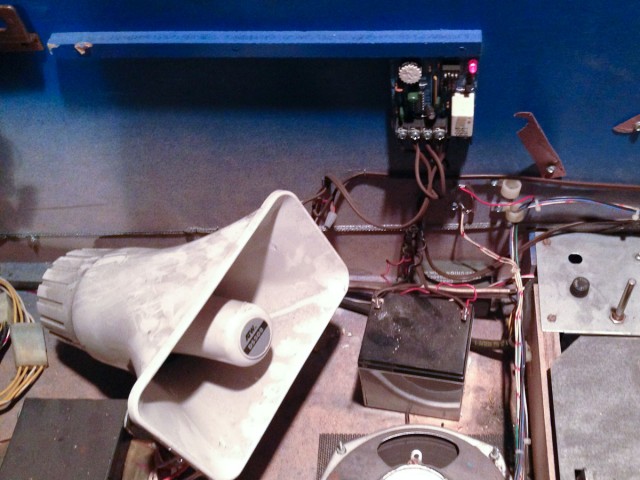

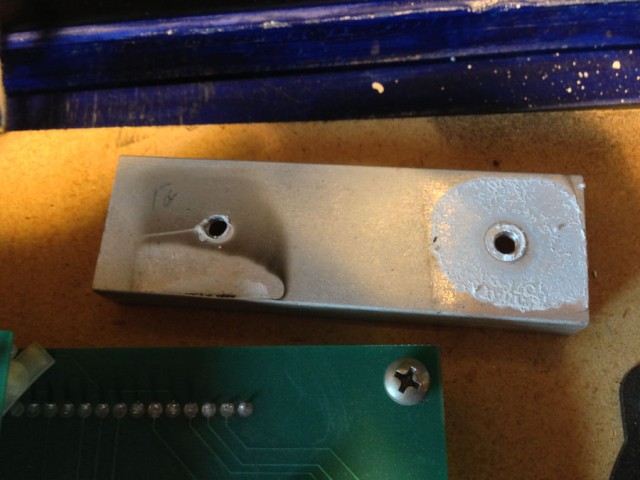

When I removed the old bridge rectifier, it was clear why it failed. When assembled at the factory, the screw was cross-threaded and the rectifier never made good contact with the heaksink.

Heatsink for bridge rectifiers on the Power/Driver Board. Left end of heatsink never had a good thermal connection with the rectifier.

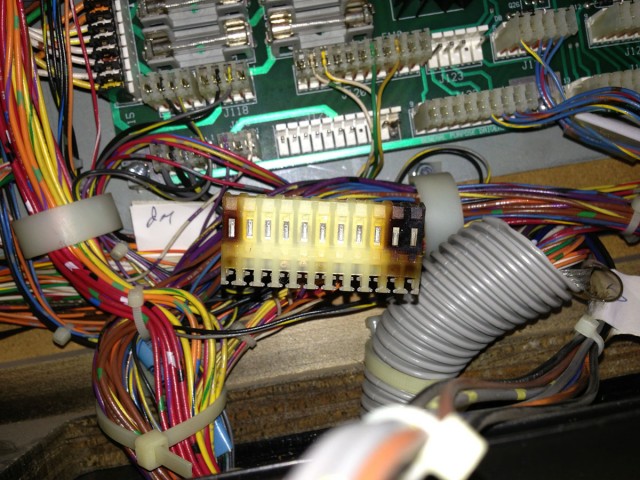

Lately, I’ve been seeing a number if issues in pinball machines where the problem originated at the factory. For example, I was recently working on a Bally Scorpion and found a staple in the wire harness on the backbox light board.

Anyway, after replacing the bridge rectifier, the machine powered up fine.