Location: Westminster, CO

Symptoms: Wouldn’t boot, flipper not working, drop target reset short, + more

Atari made a hand full of pinball machines before they closed that division to focus solely on video games. Superman is one of two games made with the 2nd generation pinball system.

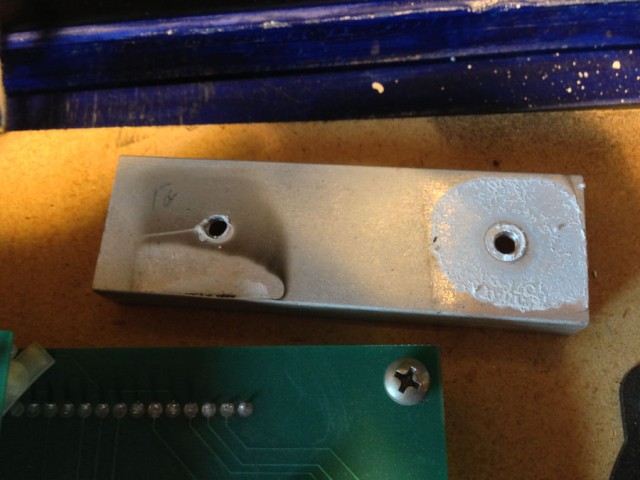

This machine had not worked for a long while while it sat in a basement. The RAM batteries had leaked. The owner thought they probably hadn’t been replaced since the 1980’s. So the first task was to get that cleaned up and locate a remote battery pack off of the board. (Unfortunately, the AnyPin NVRAM module will not work with Atari machines.)

Once I got it to boot, I discovered the left flipper didn’t work. The flipper coil was badly damaged by something hitting it. A new coil was ordered.

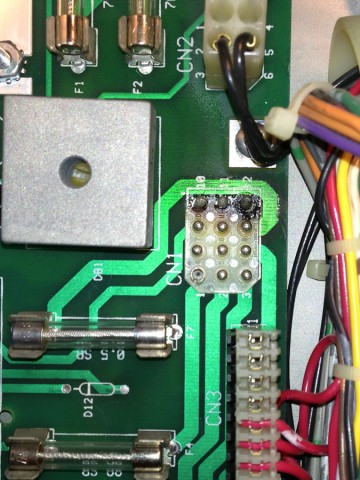

The Atari system has a coil protection circuit that is supposed to shut down the coil power if it detects a shorted coil, in order to protect the drive transistors. In this case there was a shorted transistor driving the drop target reset coil. So basically every time another playfield coil was activated, the center drop targets would reset. I replaced the transistor it the coils started acting normally. It was a bit confusing at first because unlike other pinball machines which use NPN transistors to drive the solenoids, these drive transistors are PNP.

Needless to say, with the lack of service on this machine, all of the rubber pieces were dry, cracking and brittle. So I replaced all of the rubbers, about 20 burned out lamps, and cleaned the playfield. The ball was also rusting, so I replaced that, too.

The target switches are hexagonal white, which nobody sells anymore. One of them is broken (and remains that way for now). Perhaps I’ll run across one at some point, or maybe I’ll take a rectangular target and cut the corners off.

Aside from the target switch, it’s working great. It’s the first time I played Superman and it seems like a fun game.

The owner let me borrow the complete set of schematics of this machine for scanning and will be available on the Internet Pinball Database (has not been approved as of this date).